Մաշկի խնամքի արդյունաբերությունը արագ ընդլայնվում է ամբողջ աշխարհում՝ տարբեր շուկաներում աճող պահանջարկ ունենալով caրձնակարգ մաշկի խնամքի ապրանքների հանդեպ:

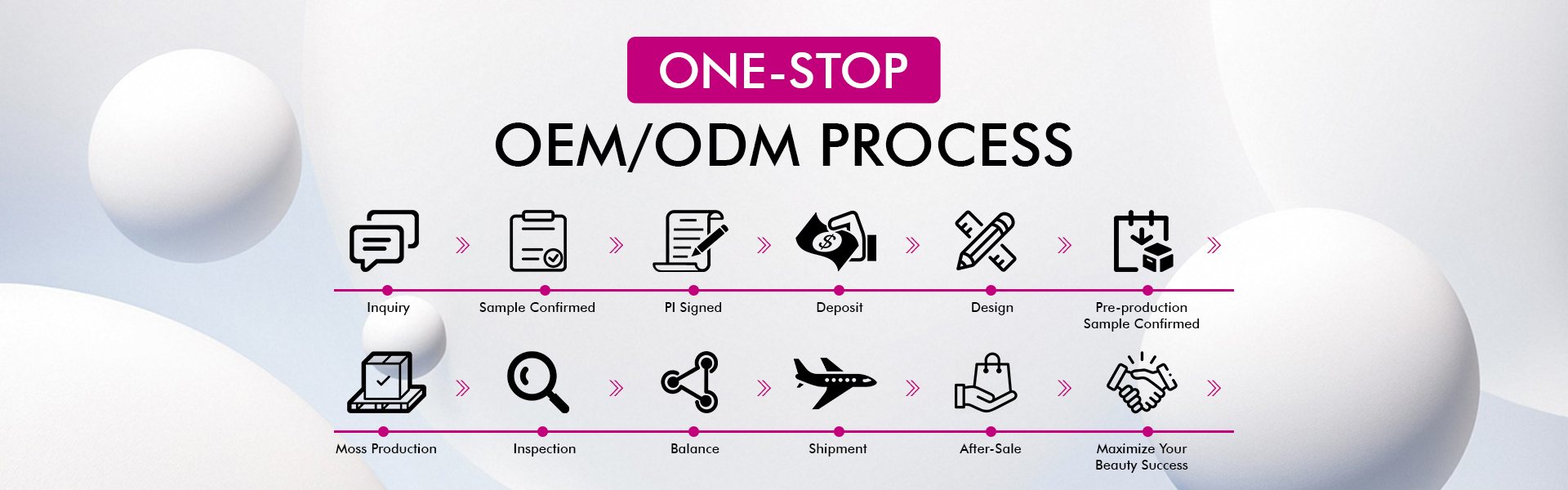

Ապրանքանիշերի համար շուկայում իրենց մաշկի խնամքի ապրանքները ներկայացնելու շատ արդյունավետ մեթոդ է հանդիսանում OEM-ի (սկզբնական սարքավորումների արտադրող) հետ համագործակցությունը:

Այս ուղեցույցը կբացատրի, թե ինչպես է աշխատում OEM մաշկի խնամքի արտադրությունը: Այն կտա ձեզ պարզ ընկալում ամբողջ գործընթացի մասին՝ սկսած սկզբնական գաղափարից մինչև պատրաստի ապրանքի իջեցումը թեքերի վրա:

OEM մաշկի խնամքի արտադրությունը վերաբերում է այնպիսի բիզնես մոդելի, երբ ապրանքանիշը իր մաշկի խնամքի ապրանքների արտադրությունը վերապրանքավորում է երրորդ կողմի արտադրողին: Ապրանքանիշը սովորաբար տրամադրում է ապրանքի տեխնիկական հատկությունները՝ ներառյալ բաղադրիչները, բաղադրությունները և փաթեթավորման դիզայնը: Այնուհետև արտադրողը խմբաքանակով արտադրում է ապրանքը՝ հիմնվելով այդ հատկությունների վրա:

ՕԵՄ-ի հետ համագործակցությունը թույլ է տալիս մաշկի խնամքի բրենդներին նվազեցնել ներքին արտադրության հետ կապված ծախսերը, հասանելիություն ստանալ առաջադեմ տեխնոլոգիաներին և փորձին ու ընդլայնել իրենց արտադրանքների առաջարկը: Չկա անհրաժեշտություն բարդ արտադրական սարքավորումներ ստեղծելու:

ԱՊՐԱՆՔԱՆԻՇԻ մաշկի խնամքի արտադրության գործընթացը պարզապես արտադրության տեխնիկական փուլերի հաջորդականություն չէ։ Մաշկի խնամքի ապրանքանիշերի սեփականատերերի համար այն հանդիսանում է ռազմավարական համակարգ, որն անմիջականորեն ազդում է մասշտաբավորման, հաստատության և երկարաժամկետ շուկայական մրցունակության վրա:

Երբ ապրանքանիշը փոքր շարքերով արտադրությունից անցնում է ավելի մեծ ծավալների, առաջանում են մեծ կարևորություն ունեցող մարտահրավերներ, ինչպիսիք են՝ բաղադրամասի կայունությունը, շարքից շարք հաստատությունը, առաքման ժամկետների կառավարումը և կանոնակարգային համապատասխանությունը։ Լավ կառուցված ԱՊՐԱՆՔԱՆԻՇԻ արտադրության գործընթացը օգնում է ապրանքանիշերին կառավարել այս փոփոխականները՝ ստանդարտացված բաղադրամասերի սխեմաների, հաստատված արտադրական աշխատանքային ընթացակարգերի և փաստաթղթերով ամրագրված որակի վերահսկման կետերի միջոցով:

Ավելի կարևոր է, որ փորձառու OEM արտադրողը արտադրման գործընթացը համաձայնեցնում է բրենդի զարգացման ռազմավարության հետ: Սա ներառում է այնպիսի ձևավորումների մշակում, որոնք կարող են մասշտաբավորվել՝ առանց կատարողականի կորստի, այն տուփավորման ընտրություն, որը համատեղելի է մեծ ծավալով լցնող գծերի հետ, և արտադրության ժամանակացույցների սահմանում, որոնք աջակցում են տարածաշրջանային ընդլայնմանը և սեզոնային պահանջարկի ցիկլերին:

Բրենդերի սեփականատերերի համար այս գործընթացը հասկանալը հնարավորություն է տալիս ավելի լավ որոշումներ կայացնել՝ մատակարարների ընտրությունից սկսած մինչև ներդրման պլանավորում: Առանձին արտադրական քայլերին սահմանափակվածության փոխարեն՝ մասշտաբավորվող OEM արտադրությունը հնարավորություն է տալիս բրենդերին ստեղծել կրկնվող համակարգ, որն աջակցում է ներդրումների դաշտի ընդլայնմանը, շուկայում ներխուժմանը և երկարաժամկետ բրենդային արժեքի կառուցմանը:

ՕԵՄ մաշկի խնամքի արտադրանք ստեղծելու ճանապարհը սկսվում է կոնցեպցիայի փուլով: Այս փուլում բրենդը նշում է իր արտադրանքի նպատակները և այն, թե ինչպես է այն բավարարելու թիրախային շուկայի պահանջները:

Առաջին քայլը ներառում է բրենդի և ՕԵՄ արտադրողի միջև հստակ կապը: Բրենդը ներկայացնում է իր տեսլականը՝ արտադրանքի նպատակների վերաբերյալ, ինչպես օրինակ՝ մաշկի ծերացման դեմ, լուսավորում, խոնավացում կամ այլ մաշկի խնդիրներ: Նաև նշվում են ցանկացած եզակի առավելություններ, ինչպես օրինակ՝ բնական կամ օրգանական բաղադրիչներ, կենդանիների վրա փորձարկումներ չանելու հայտարարություններ կամ դերմատոլոգի ստուգած արտադրանքներ:

Սա կարևոր փուլ է, քանի որ արտադրողը պետք է հասկանա բրենդի նպատակները՝ նախքան ձևավորումն ու արտադրությունը շարունակելը:

Երբ հայեցակարգը սահմանված է, միանում է արտադրողի հետազոտության և մշակման (R&D) թիմը: Այս փուլում R&D-ի փորձագետները աշխատում են ապրանքի ձևավորման վրա՝ բավարարելու բրենդի պահանջները: R&D-ի թիմերը կենտրոնանում են այնպիսի բաղադրատոմսերի ստեղծման վրա, որոնք ոչ միայն արդյունավետ են, այլ նաև անվտանգ՝ սպառողների համար: Սա ներառում է ապրանքների ձևավորումը՝ ճիշտ pH հավասարակշռությամբ, կոնսիստենտությամբ և հոտով:

Կախված ապրանքի բարդությունից՝ արտադրողները կարող են մասնագիտական R&D կենտրոնի հնարավորություններից օգտվել տարբեր բաղադրիչներ փորձարկելու համար՝ համոզվելու համար, որ դրանք համապատասխանում են որակի և կանոնակարգային չափանիշներին:

Բանաձևի մշակումից հետո արտադրողը ընդունակ է արտադրելու նմուշ-պրոտոտիպ՝ ըստ բրենդի հաստատման: Սա գործընթացի կարևոր մասն է, քանի որ հնարավորություն է տալիս բրենդին փորձարկել ապրանքը և կարծիք հայտնել: Եթե անհրաժեշտ է կատարել որևէ կարգավորում, օրինակ՝ հոտ, կոնսիստենտություն կամ տեքստուրա, ապա արտադրողը կարող է կատարել այդ փոփոխությունները մինչև սերիական արտադրությունը սկսելը:

Ապրանքի գաղափարը ավարտվելուց հետո ճիշտ բաղադրիչներ գտնելը կարևոր է: Սա ապահովում է այն բանը, որ մաշկի խնամքի ապրանքը կատարում է իր խոստումները: OEM արտադրողներն ունեն հաստատված հարաբերություններ վստահելի մատակարարների հետ, ովքեր բարձրորակ հումք են տրամադրում: Կախված թիրախային լսարանից և ապրանքի հայտարարություններից՝ բրենդերը կարող են ընտրել բնական, օրգանական կամ սինթետիկ բաղադրիչներ:

Որակը հիմնական կենտրոնացման կետ է: Բաղադրիչները պետք է համապատասխանեն տեղական և միջազգային ստանդարտներին (ինչպես, օրինակ, FDA-ի նորմատիվները ԱՄՆ-ում կամ Եվրոպայի համար կոսմետիկայի կանոնակարգը): Բացի այդ, ստեղծված է հետևողականության համակարգ, որը երաշխավորում է, որ օգտագործվող բաղադրիչները անվտանգ, համապատասխան և էթիկապես ստացված են:

Բաղադրությունը այն տեղն է, որտեղ տեղի է ունենում հրաշքը: OEM արտադրողի փորձագետները ընտրված բաղադրիչների միջոցով ստեղծում են վերջնական արտադրանքը: Սա մի նրբագեղ գործընթաց է: Այս գործընթացում ակտիվ բաղադրիչների, կոնսերվանտների և հիմնական բաղադրիչների ճիշտ համամասնությունը պետք է հավասարակշռված լինի:

Յուրաքանչյուր բաղադրություն ենթարկվում է խիստ փորձարկումների՝ համոզվելու համար, որ այն անվտանգ, կայուն և արդյունավետ է: Որոշ արտադրողներ կայունության փորձարկումների համար օգտագործում են առաջադեմ կոսմետիկական լաբորատորիաներ, որոնք երաշխավորում են, որ արտադրանքը ժամանակի ընթացքում պահպանում է իր արդյունավետությունը:

Փաթեթավորումը ավելի շատ է, քան պարզապես տարա. այն ապրանքանիշի ինքնության կարևոր մասն է: Ուժեղ փաթեթավորման դիզայնը կարող է որոշող լինել ապրանքի հաջողության համար խանութի թեքանիվների վրա: Այս փուլում ապրանքանիշը համագործակցում է արտադրողի հետ՝ ընտրելու համապատասխան փաթեթավորում, որը արտացոլում է ապրանքանիշի արժեքներն ու ապրանքի նպատակները:

Օրինակ, լավագույն կանխատեսումների ապրանքանիշերը կարող են ընտրել բարձրակարգ ապակե տարաներ, իսկ էկոլորտի ապրանքանիշերը կարող են նախընտրել կենսաքայքայվող կամ վերամշակվող փաթեթավորում: Մշակվում են նաև հատուկ պիտակների դիզայններ՝ սպառողներին ապրանքի առավելություններն ու բաղադրիչները հաղորդելու համար: Այս փաթեթավորման փուլը նաև ներառում է փաթեթավորման օգտագործողաբար հարմար և գործառույթային լինելու ապահովումը:

Նախքան սերիական արտադրությունը սկսելը, փաթեթավորման դիզայններն ու պրոտոտիպերը վերանայվում և հաստատվում են: Արտադրողները ստեղծում են մակետներ և ուղարկում բրենդին՝ վերջնական հաստատման: Եթե անհրաժեշտ է որևէ փոփոխություն, այն կատարվում է այս փուլում՝ վերջնական արտադրանքի ճիշտ էսթետիկ և գործառույթային հատկանիշները ապահովելու համար:

Պատվերների արտադրության գործընթացը սկսվում է փաթեթավորման նախագծերի հաստատումից հետո: OEM մաշկի խնամքի արտադրողների մեծ մասը գործում է GMP- ի կողմից հավաստագրված (Լավ արտադրական պրակտիկա) հաստատություններում, որոնք համապատասխանում են բարձրորակ արտադրական ստանդարտներին: Այսինքն, նրանք օգտագործում են ամենաարդյունավետ սարքավորումներ եւ աշխատում են վերահսկվող միջավայրում, որպեսզի ապահովեն արտադրանքի համահունչությունը եւ անվտանգությունը:

Արտադրողի արտադրական հզորությունը մեծ դեր է խաղում այն ժամանակացույցի և քանակների վրա, որոնք բրենդը կարող է արտադրել: Livepro-ն ունի 90,000+ քառ. մ արտադրական հարթակ, 30+ բարձր ստանդարտ արտադրական գիծ և 1,000,000+ ապրանքի ամենօրյա արտադրության հզորություն: Եթե բրենդերին աշխարհահռչակ շուկայի համար միլիոնավոր միավորներ արտադրելու անհրաժեշտություն ունեն, մենք կարող ենք ամբողջությամբ բավարարել դրանք:

Այս փուլի ընթացքում հումքը խառնվում է՝ վերածվելով վերջնական արտադրանքի: Արտադրողը օգտագործում է հատուկ սարքավորումներ՝ ակտիվ բաղադրիչները հիմնական բանաձևին խառնելու համար: Երբ արտադրանքը պատրաստ է, այն լցվում է ընտրված փաթեթավորման մեջ՝ անկախ նրանից, թե դա շշեր են, տուփեր, թե խողովակներ, և կնքվում է փոխադրման համար:

Թույլատրված լցման տեխնոլոգիաները ապահովում են արտադրանքի ճշգրիտ քանակի լցումը յուրաքանչյուր տարայի մեջ՝ ապահովելով համազորություն և ճշգրտություն:

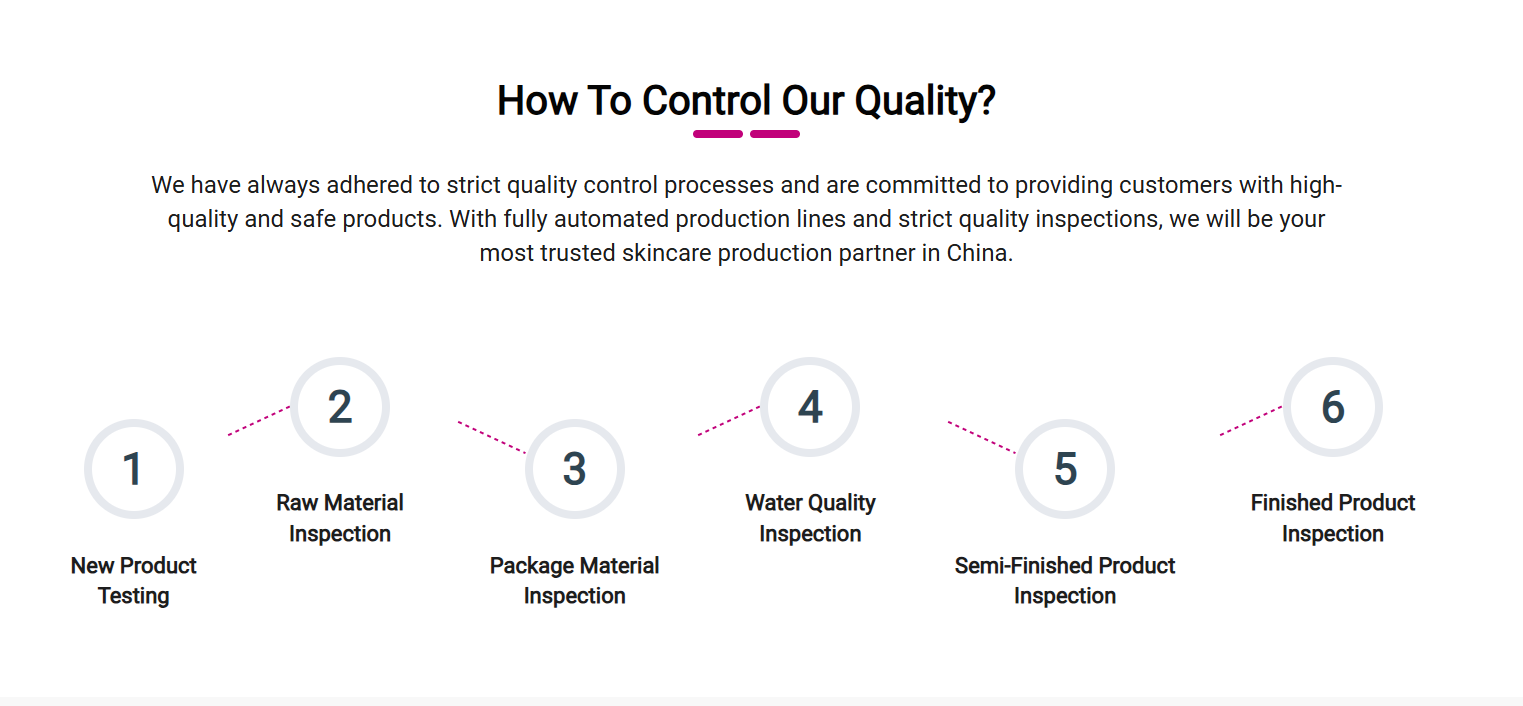

Արտադրանքը արտադրության գործընթացի յուրաքանչյուր փուլում անցնում է որակի վերահսկման ստուգումներ: Այս ստուգումները ապահովում են, որ վերջնական արտադրանքը համապատասխանում է մաքրության, համահունչության եւ անվտանգության անհրաժեշտ չափանիշներին: Որոշ արտադրողներ նույնիսկ կլինիկական փորձարկումներ են իրականացնում արտադրանքի պնդումները հաստատելու համար (օրինակ ՝ "հիպոալերգենիկ" կամ "հակ ծերացում") ։

Ապրանքը գլոբալ շուկայում վաճառելու համար անհրաժեշտ է, որ այն համապատասխանի տեղական կանոնակարգերին: ԱՄՆ-ում սա նշանակում է կոսմետիկայի համար FDA-ի ուղեցույցներին հետևելը: Եվրոպական Միությունում ապրանքը պետք է համապատասխանի ԵՄ կոսմետիկայի կանոնակարգին՝ ապահովելով անվտանգության, պիտակավորման և հայտարարությունների չափանիշներին համապատասխանություն:

OEM արտադրողները օգնում են ապրանքային նշաններին այդ կանոնակարգերի միջոցով անցնել և հաճախ կատարում են արտադրանքի գրանցումները՝ ապահովելով, որ յուրաքանչյուր արտադրանք օրինական կերպով շուկայավարվի:

Կոշտությունից ազատ, վեգան, օրգանական կամ դերմատոլոգիապես փորձարկված հավաստագրման պիտակները կարող են բարձրացնել ապրանքի հարկավորությունը։ OEM արտադրողը աշխատում է երրորդ կողմի կազմակերպությունների հետ՝ այս հավաստագրումները տրամադրելու համար։ Այսպիսով, նրանք կարող են ավելի շատ տարբերակել բրենդը խիտ շուկայում։

Արտադրությունից հետո ապրանքը պետք է վերջնական փաթեթավորվի։ Սա ներառում է տարաների կնքումը, պիտակների ճիշտ կիրառումը և ապրանքի բոլոր կանոնական պահանջներին համապատասխանության ստուգումը (բաղադրիչների ցանկ, օգտագործման հրահանգներ և այլն)։

Վերջնական փաթեթավորումը պետք է արտացոլի նաև բրենդի ինքնությունն ու հաղորդագրությունը։ Այս պատճառով այս քայլը կարևոր է ապրանքատեսակի միջև համա consistency պահպանման համար։

Փաթեթավորմանից հետո կատարվում է որակի ստուգման ևս մեկ փուլ։ Սա ներառում է փաթեթավորման հնարավոր թերությունների ստուգում, ապրանքի համազանգվածության փորձարկում և արտադրանքի ընդհանուր տեսքի հաստատում։ Եթե հայտնաբերվեն խնդիրներ, այդ միավորները հեռացվում են շարքից։

Վերջնական արտադրանքը զգուշությամբ փաթեթավորվում է տրանսպորտային փոխադրման համար։ Ճիշտ փաթեթավորումը պաշտպանում է արտադրանքը փոխադրման ընթացքում վնասվածքներից։ Հատկապես այն դեպքերում, երբ արտադրանքը պարունակում է զգայուն բաղադրիչներ, ինչպիսիք են ակտիվ բուսական նյութերը կամ էթերայուղերը։

Այս փուլում տրանսպորտային ընկերությունները արտադրանքը տեղափոխում են ապրանքանիշի բաշխման կենտրոն կամ ռետայլ կետեր։ Այս քայլը կարող է ներառել միջազգային փոխադրումներ, таможնային մաքրում և պահեստային պահում։

![Packing & Delivery].png](https://shopcdnpro.grainajz.com/category/25713/1656/64a083b098b2e52ccab1b4c5c9611fee/Packing_%26_Delivery%5D.png)

Նույնիսկ ապրանքները փոխադրելուց հետո OEM արտադրողը կարող է շարունակել աջակցություն ցուցաբերել: Սա կարող է ներառել խնդիրների լուծում, սպառողներից հետադարձ կապի տրամադրում կամ արտադրական գործընթացի ճշգրտում՝ կախված շուկայի հետադարձ կապից:

Կախված արտադրողի և բրենդի միջև կնքված համաձայնագրից՝ OEM-ն կարող է նաև կառավարել պաշարները և դրանք համալրել: Սա ապահովում է, որ բրենդը կարողանա բավարարել շուկայական պահանջարկը՝ առանց պաշարների սպառման մասին անհանգստանալու:

OEM մաշկի խնամքի արտադրողի հետ համագործակցությունը շատ առավելություններ է տալիս այն բրենդերի համար, որոնք ձգտում են պարզեցնել արտադրության գործընթացները և արագ, արդյունավետ շուկա հասցնել իրենց ապրանքները: Արտադրությունը արտաքին կազմակերպությանը վստահելով՝ բրենդերը կարող են կենտրոնանալ իրենց հիմնական ուժերի վրա՝ ինչպիսիք են մարքեթինգը, բրենդինգը և վաճառքը, մինչդեռ հենվում են արտադրողի փորձի և ենթակառուցվածքի վրա՝ արտադրության բարդությունները կառավարելու համար:

Ճիշտ OEM մաշկի խնամքի արտադրողի ընտրությունը կարևոր որոշում է, որն կարող է ձեր ապրանքանիշի արտադրանքի ներկայացման հաջողությունը կամ ձախողումը որոշել: OEM գործընկեր ընտրելիս հաշվի առեք հետևյալ գործոնները.

Եզրափակելով՝ փորձառու և կարող ՕԵՄ ծերուկի խնամքի արտադրողի հետ համագործակցելն օգնում է բարձրացնել ձեր բրենդի արտադրանքների որակը, կրճատել ծախսերը և արագացնել շուկա դուրս գալու ժամանակը: Ճիշտ գործընկեր ընտրելով՝ կարող եք սպառողներին առաջարկել բարձրորակ ծերուկի խնամքի արտադրանքներ՝ ձեր ջանքերը կենտրոնացնելով բրենդի աճի և շուկայավարման վրա:

1) Ի՞նչ է ծերուկի խնամքի արտադրության գործընթացը

Տիպիկ կեղևային խնամքի արտադրության գործընթացը GMP գործարանում ներառում է արտադրանքի նախապատրաստում, բաղադրամասերի ձևավորում, լաբորատորիայում փորձարկում, կայունության և միկրոկենսաբանական փորձարկումներ, համատեղելիության ստուգում փաթեթավորման հետ, փորձնական շարք, խմբաքանակի արտադրություն, լցում, վերջնական որակի վերահսկում և առաքում: Ճշգրիտ քայլերը տարբերվում են կախված արտադրանքի տեսակից (ստվար, տոներ, արևի ֆիլտր, դիմակ) և բաղադրամասի ռիսկի մակարդակից:

2) Ինչպե՞ս են արտադրվում կեղևային խնամքի արտադրանքները գործարանում (քայլ առ քայլ):

Շատ գործարաններ հետևում են նույն հիմնական աշխատանքային հոսքին. հումքի ստուգում → կշռում → էմուլսիա կամ խառնում → սառեցում → pH/խտության ճշգրտում → ընթացակարգի ընթացքում որակի ստուգումներ → պահեստային տանկ → լցում → փականների կամ կնիքի տեղադրում → պիտակավորում/փաթեթավորում → վերջնական ստուգում: GMP պահանջները կենտրոնանում են հիգիենայի վերահսկման, փաստաթղթավորման և յուրաքանչյուր փուլում հետևելիության վրա:

3) Խմբաքանակի արտադրությունից առաջ որո՞նք են պահանջվող փորձարկումները

Մինչև զանգվածային արտադրության անցումը՝ գործարանները, սովորաբար, կատարում են կայունության փորձարկում (ջերմաստիճանային ցիկլեր և հասունացում), միկրոկենսաբանական փորձարկում (բաղադրության անվտանգությունը հաստատելու համար) և փաթեթավորման համատեղելիության փորձարկումներ (համոզվելու համար, որ բաղադրությունը չի փոխազդում շիշի, պոմպի կամ պատյանի հետ): Որոշ ապրանքների համար կարող են պահանջվել լրացուցիչ ստուգումներ, ինչպիսիք են կոնսերվանտի արդյունավետության/մարտահրավերի փորձարկումը կամ SPF-ին առնչվող վավերացումը՝ կախված շուկայից:

4) Որքա՞ն է կեղևային խնամքի արտադրության ժամանակահատվածը:

Ժամանակացույցը կախված է նրանից, թե արդյոք բաղադրությունը արդեն գոյություն ունի, թե նոր է մշակվել: Սովորական մասնավոր պիտակի նախագիծը ներառում է նմուշի մշակում և փոփոխություններ, փորձարկում/վավերացում, փաթեթավորման հաստատում, ապա զանգվածային արտադրություն և լցում: Ինքնըստինքյան արտադրությունը կարող է համեմատաբար արագ լինել, սակայն փորձարկումներն ու հաստատումները հաճախ են լինում իրական ժամանակային գործոններ՝ հատկապես կայունությունը, միկրոկենսաբանությունը և փաթեթավորման համատեղելիությունը:

5) Ո՞րն է OEM և մասնավոր պիտակի կեղևային խնամքի տարբերությունը:

Անհատական պիտակը, որպես կանոն, նշանակում է, որ դուք ընտրում եք արդեն գոյություն ունեցող բաղադրատոմսը և փոխում եք ապրանքային նշանը/փաթեթավորումը։ OEM-ն (և երբեմն «ստեղծված բաղադրատոմս») սովորաբար ներառում է բաղադրատոմսի փոփոխություն կամ մշակում, հումքի ընտրություն և արդյունավետության նպատակների սահմանում։ Փաստացի, աշխատանքային հոսքը նույնն է, սակայն OEM նախագծերը սովորաբար ավելի շատ փորձարկումներ են և հաստատումներ պահանջում մեծ քանակով արտադրության սկզբից առաջ: